Quick Links

Biofilm management and control

A biofilm is a layer of microorganisms contained in a matrix (slime layer), which forms on surfaces in contact with water. Incorporation of pathogens in biofilms can protect the pathogens from concentrations of traditional disinfectants that would otherwise kill or inhibit those organisms freely suspended in water.

Biofilms provide a safe haven for organisms like Listeria, E. coli and legionella where they can reproduce to levels where contamination of products passing through that water becomes inevitable.

Where Biofilms Form

Biofilms happily colonize many household surfaces in the water tanks and pipelines, bath and kitchen, including toilets, sinks, countertops, and cutting boards. Poor disinfection practices and ineffective cleaning products may increase the incidence of illnesses associated with pathogenic organisms encountered during normal household activity, and also water cycle specially in cooling and heating systems commonly found in facilities such as hospitals, airports and hotels which is can be a breeding ground for Legionella and Pseudomonas bacterium

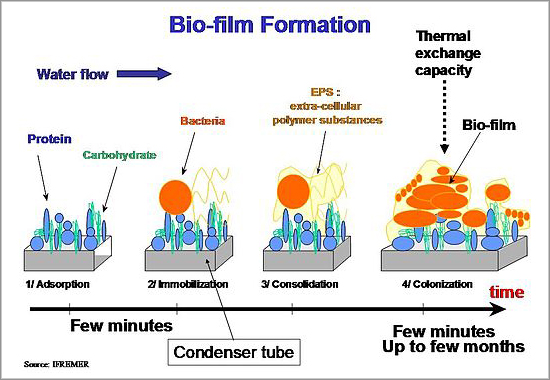

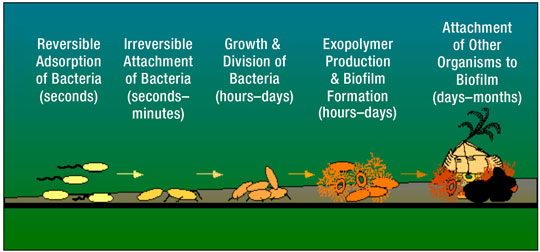

How Biofilms Form

Free-swimming bacterial cells land on a surface, arrange themselves in clusters, and attach.

The cells begin producing a gooey matrix.

The cells signal one another to multiply and form a micro-colony.

The micro-colony promotes the coexistence of diverse bacterial species and metabolic states.

Some cells return to their free living form and escape, perhaps to form new biofilms.

Biofilm and Your Health

Biofilms are highly resistant to traditional disinfectants. Consequently, very high and/or long-term doses are often required to eradicate biofilm-related infections. Biofilms are responsible for diseases, such as:

Otitis media the most common acute ear infection in US children

Bacterial endocarditis infection of the inner surface of the heart and its valves

Cystic fibrosis a chronic disorder resulting in increased susceptibility to serious lung infections

Legionnaire's disease an acute respiratory infection resulting from the aspiration of clumps of Legionella biofilms detached from air and water heating/cooling and distribution systems

Hospital-acquired infections infections acquired from the surfaces of catheters, medical implants, wound dressing, or other medical devices

The role of bacterial biofilms in chronic infections.

Acute infections caused by pathogenic bacteria have been studied extensively for well over 100 years. These infections killed millions of people in previous centuries, but they have been combated effectively by the development of modern vaccines, antibiotics and infection control measures. Most research into bacterial pathogenesis has focused on acute infections, but these diseases have now been supplemented by a new category of chronic infections caused by bacteria growing in slime-enclosed aggregates known as biofilms. Biofilm infections, such as pneumonia in cystic fibrosis patients, chronic wounds, chronic otitis media and implant- and catheter-associated infections, affect millions of people in the developed world each year and many deaths occur as a consequence. In general, bacteria have two life forms during growth and proliferation. In one form, the bacteria exist as single, independent cells (planktonic) whereas in the other form, bacteria are organized into sessile aggregates. The latter form is commonly referred to as the biofilm growth phenotype.

The potential for biofilm growth in water distribution systems.

Biofilms on water tanks and internal pipe walls in water distribution systems are composed of bacteria in a polymeric matrix, which can lead to disinfectant demand, coliform growth, pipe corrosion and water taste and odour problems. The majority of previous studies have been laboratory or pilot plant based and few results are available for field conditions. In a lot of studies, field observations of biofilm were made using biofilm potential monitors. The monitor results were compared with pipe samples taken from the distribution system and with laboratory pipe reactors. The using of our most greatest disinfectants "Peroxy plus® products" are effective and powerful to remove the biofilm layer and that referring to the penetration effect to biofilm layer and destroying the Bacteria content, the three way mechanism of action of "Peroxy plus® products" which is support the effectiveness against the biofilm layer.

How "Peroxy plus® products"destroy the biofilm layer and remove it ?

The hydroxyl free radical "OH̊" released in rich form from the content of "Peroxy plus® products" which is responsible about the degradation effect of Biofilm, but this effect not afforded without the stabilization effect of Silver ions which is manage the contact time in degradation mechanism.

As known the Advanced Oxidation Process "AOP" and the main concept of it is mechanism of action is depend on the stabilization effect contact time of hydroxyl free radical "OH̊" are the key for all these kinds of reactions.

So, Rein Product discovered these keys and introduced it in one formula "Peroxy plus® products".

Automatic dosing "Miller® Products""Biofilm Management andcontrol"

As the Chinese saying goes Prevention is better than Cure, the Automatic dosing system of "Miller® Products" to water cycle specially in cooling and heating systems commonly found in facilities such as hospitals, airports and hotels which is can be a breeding ground for Legionella and Pseudomonas bacterium, it can get rid of that problem before start

So, we must "manage" biofilm in three ways:

• Remove the biofilm matrix for the untreated before system this is will manage with "Peroxy plus® products".

• Remove or destroy the organisms for the untreated before system this is will manage with "Peroxy plus® products".

• Prevent the biofilm for the new system and this is will manage with "Miller® Products"by using Periodic "shock" and continuous dosage.

.jpg)